Drive Applications

FAULHABER has comprehensive range of high-precision micro stepper motors, integrated linear components, and lightweight DC or brushless DC motors are suitable for many applications and can coupled with integrated encoders and sensors and other custom elements to optimize suitability where it matters.

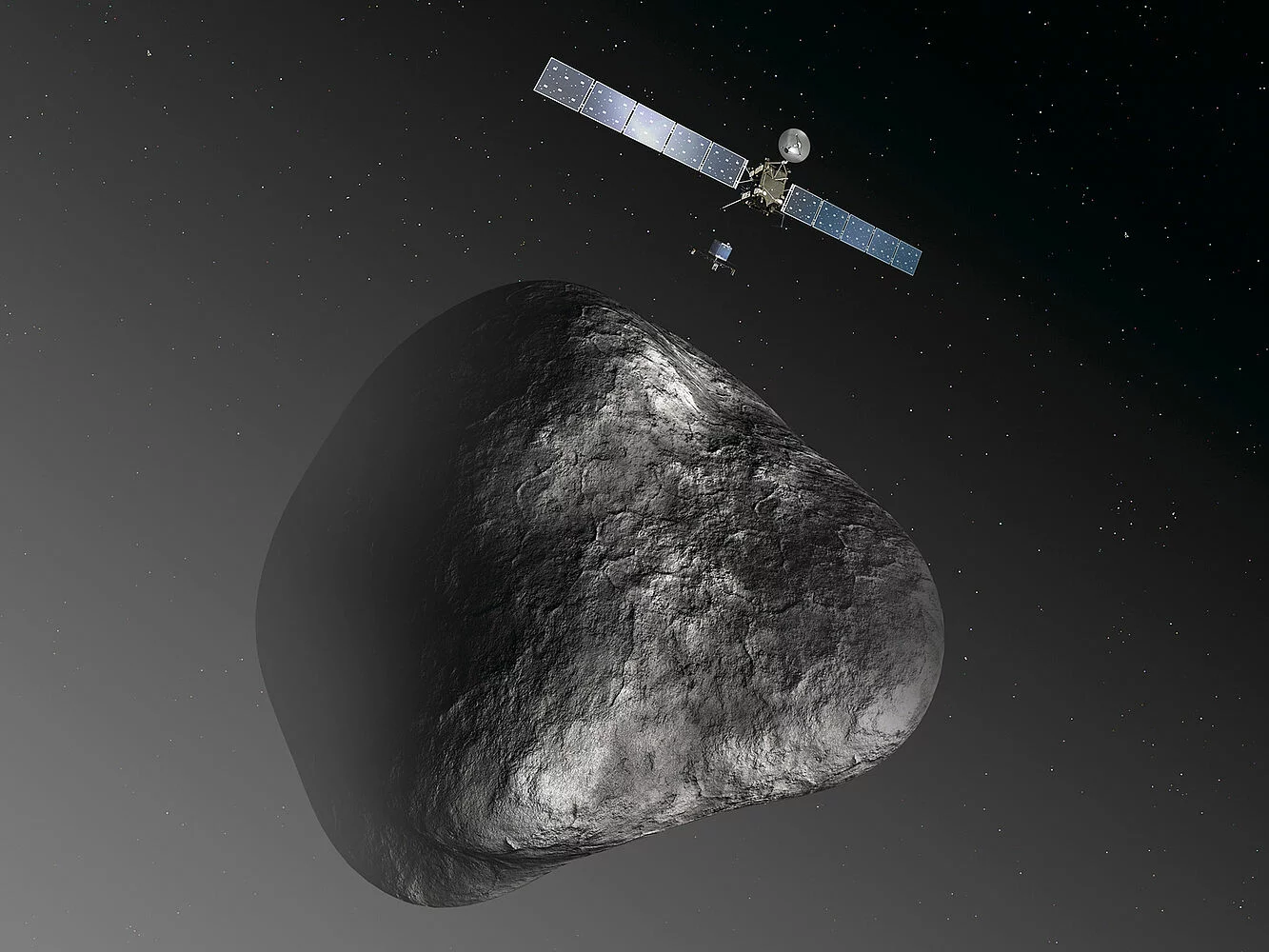

Aerospace & Aviation

From the vastness of outer space to the demands of civil aviation, FAULHABER's drive solutions excel under extreme mechanical stress, delivering flawless performance. Innovative materials and cutting-edge processes are the foundation of aerospace advancements. Manufacturers can rely on FAULHABER for high-efficiency, lightweight drive systems that offer the following:

- Robust design

- High-torque or high-speed with small size and low weight

- Works reliably in vacuum

- Reliable at extremely low temperatures

- Operate perfectly under high mechanical stress

- Compliance with safety regulations

Medical

Drive systems are integral to medical advancements, ensuring flawless performance where failure is not an option. Application examples include Endodontics and surgical hand tools where high speed and slow temperature to maintain comfort for practitioners is desirable. Surgical robotic applications where a small drive can provide precise haptic feedback for surgeons, to enable perfect incisions. Prosthetics where a quiet drive empowers a user with seamless daily functionality, free from battery concerns or disruptive noise. FAULHABER devices offer the following for these types of applications.

- Low noise

- Highest precision and reliability

- Low weight

- Compact high-torque drives with zero-backlash gearheads excel in tight spaces.

- Autoclavable options meet stringent hygiene requirement.

Robotics

Today, robots are ubiquitous—from space exploration to manufacturing and agriculture. FAULHABER drive systems meet the demanding requirements of these applications, ensuring precision and reliability. Examples include logistics where picking items to preparing shipping with speed, reliability, and high torque in a compact size is critical. Inspection robots, vital for tasks like sewer maintenance, benefit from FAULHABER's robust CR series and brushless BXT series with GPT planetary gearheads, conquering harsh environments underground. FAULHABER drives, known for their compact size, endurance, and performance, are the backbone of success in challenging robotic applications and offer the following.

- High precision

- Long service life and reliability

- Low maintenance requirements

- Minimal installation space

- Dynamic start/stop operation.

Optics

From capturing last-minute free kicks to life-saving rescue operations, and exploring the universe with microscopes and telescopes, FAULHABER micromotors ensure perfect positioning of optical components in critical moments. Optics and precision have always been intertwined, especially in devices like microscopes, night-vision equipment, and lasers. FAULHABER motors meet the highest demands, providing utmost precision, compact size, minimal vibrations, and heat emission. They excel in confined spaces, delivering unmatched speed control and energy efficiency.

- Highest precision and reliability

- Lightweight design

- Extremely long operational lifetimes

- High dynamic positioning

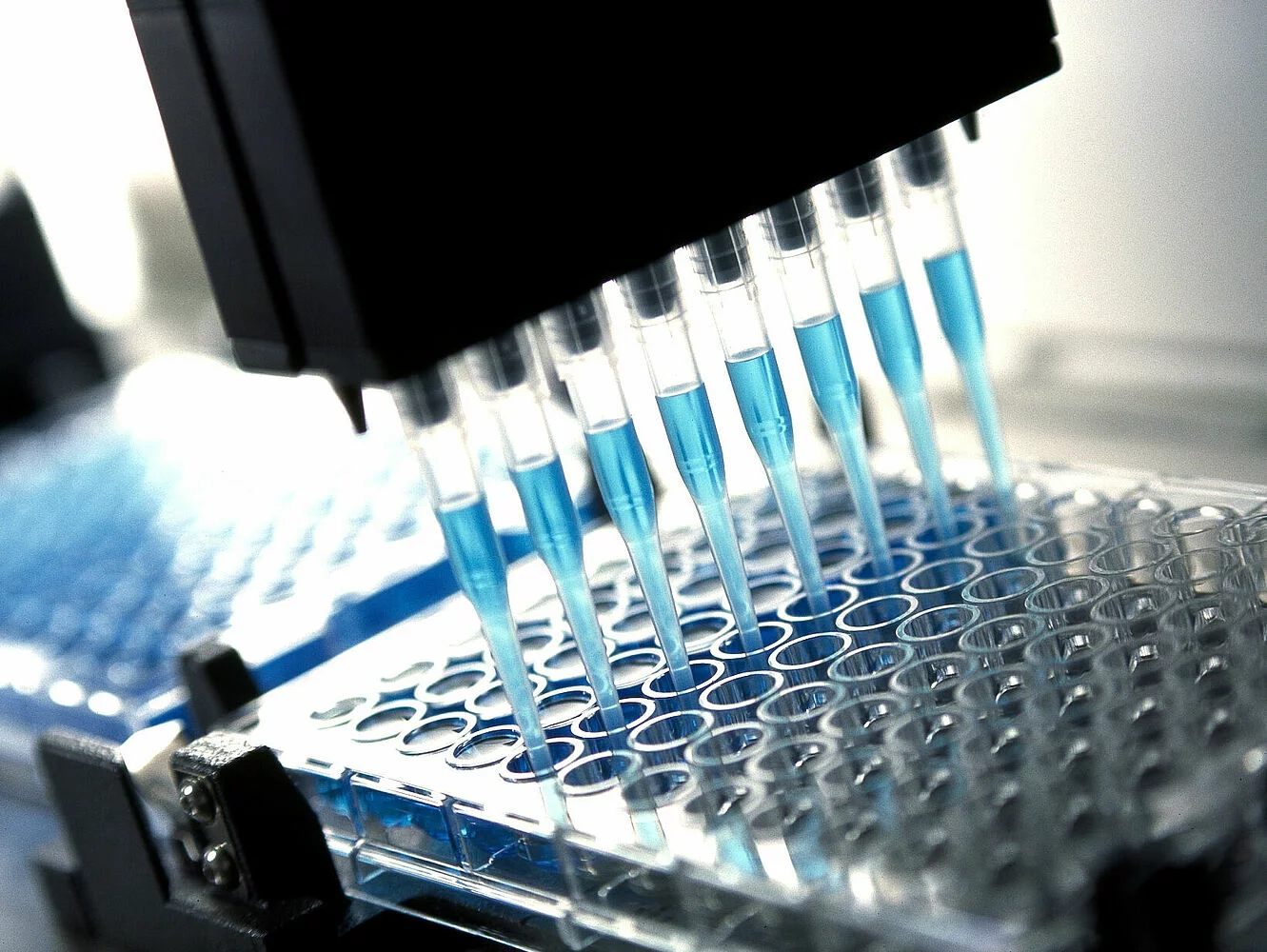

Lab Automation

Drive systems can ensure reliable analyses in both central laboratories and point-of-care (PoC) systems. In lab automation, our drives deliver precision and speed for a head start in diagnostics.

Point-of-care (PoC) systems offer cost-effective, rapid, and reliable results with minimal training, ideal for on-site analysis of medical samples. For mass testing like COVID-19 screenings, large-scale automated laboratories are essential due to their high throughput capabilities. Our drive solutions power various lab automation applications, from XYZ liquid handling to test tube decapping, sample transportation, liquid dosing with pipettors, and mixing tasks.

- Complete solutions consisting of motor, gearhead, encoder and controller Compact design and light weight for highly dynamic movements in the machines Wide range of rotary and linear motors

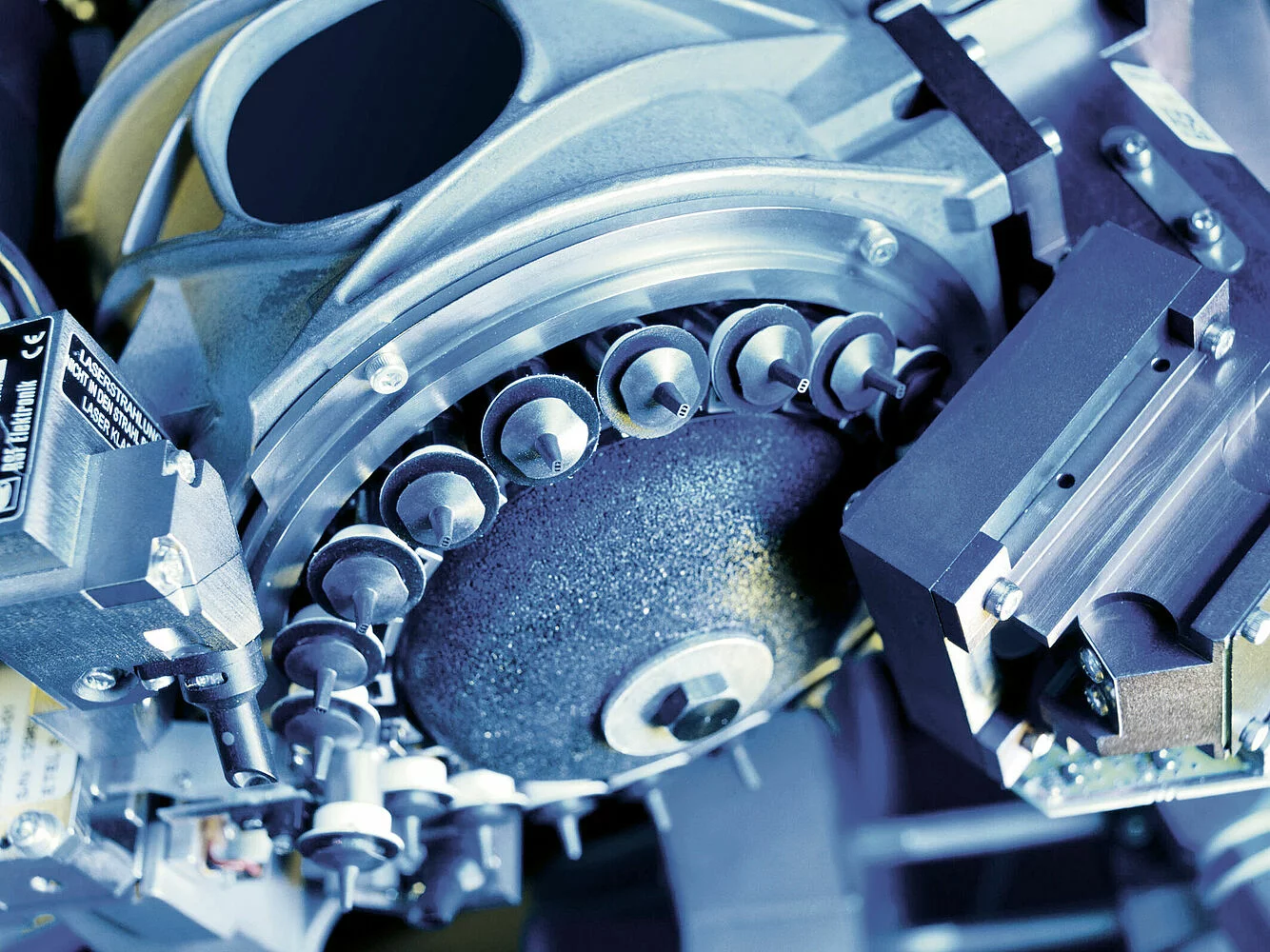

Industrial Automation

Since Henry Ford integrated the assembly line in 1914, industrial production has evolved dramatically. Today, automation is indispensable for process safety, reliability, and economic efficiency in modern production lines. In the era of Industry 4.0, factories merge IT and manufacturing, enabling seamless coordination between machines. FAULHABER drives play a crucial role in this revolution, integrating with actuators and sensors for automated manufacturing. From SMT assembly machines to electrical grippers and conveyor systems, our drive systems excel in precision and reliability, fitting seamlessly into Industry 4.0 applications. With high-performance DC-motor controllers and standardized interfaces like CANopen or EtherCAT, configuration integration can be simple and secure. Benefits of FAULHABER drives:

- Highest precision and reliability

- High dynamic positioning

- Compact size and lightweight design

- Long operational lifetimes

- Compatibility with various industry standard interfaces